Heating a boat workshop is a challenge when the boat shop in question is a bay in a 70-year-old detached garage with wood siding and no insulation. Upstate New York winters are cold and I’d like to continue to work on the boat as long as possible. But I also have to maintain a minimum working temperature for the epoxy so I have to solve for both scenarios.

At first, I focused on raising the temperature of the entire space but how would I do that without investing the little time I have on insulating the garage? I thought, “Maybe I can tent in the work area…” But the more I looked at it, the more unlikely it seemed.

The would-be “ceiling” is punctuated with all sorts of things – fluorescent fixtures, electric cables, junction boxes, etc. Each represents a break in the envelope which defeats the goal. I’d also need to create a curtain between the bays but that is also impractical. I’m already trying to build in a limited space and a curtain would cut me off from the few feet of space shared between my work bay and the car bay. Fortunately, I found my answers in the article Epoxy in Cold Weather from the CLC Boats website.

Making for a Happy Boatbuilder

Keeping myself warm turns out to be easier than I thought. An indoor safe space heater will do the trick of providing enough heat to keep working. So, I picked up the Mr. Heater Big Buddy propane heater for this purpose. It runs off 1 lb cylinders which, while convenient, is pricey. Running off of a 20lb cylinder is far more cost effective so I also picked up a 10′ Mr. Heater Buddy Series Hose Assembly. I specifically chose this one because its material doesn’t require a filter like other lines. Other lines let out small amounts of oil which will eventually gum up the heater.

Dealing with Smaller Glue-Ups

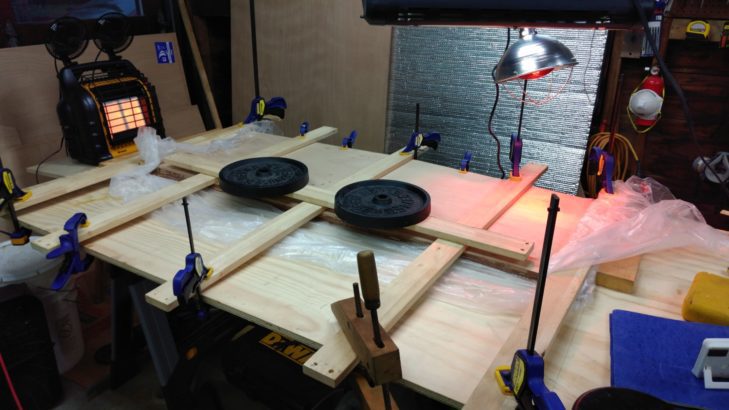

For smaller glue ups, infrared heat is the way to go. I’ll enlist a Bayco Brooder Clamp Light and a 1500 watt infrared heater placed directly over the work. I did some testing and this should work out well. With the outside temperature about 40 degrees, I turned on both heaters and pointed them at the work surface.

After 10 minutes, I used an instant-read infrared thermometer to check an area roughly 66″ long by 25″ wide which is the size of the transom. Temperatures ranged from just under 70 degrees at the edges and into the 120s toward the middle. In later tests, I tweaked the placement of the two heat sources in order to get a more uniform temperature distribution closer to the 70-90 degree range at a similar outdoor temperature.

Curing Epoxy Over Larger Surfaces

Large surface cures are where heating a boat workshop starts to become a challenge. Pouring heat into a large uninsulated will get expensive very quickly. Fortunately, tenting the boat is a viable way to address this. A clothesline suspending plastic sheeting over the boat should be just enough to contain the heat of a carefully placed 1500 watt electric heater and ensure the epoxy cures.

Unmixed Epoxy Needs Warmth Too

Finally, there’s the epoxy itself. The colder the unmixed epoxy get – the resin and hardener – the more viscous it becomes and the harder it is to work with. And at some point, you hit the lower end of the working temperature for the epoxy. In the case of the Raka Epoxy I’m using, it is 60 degrees Fahrenheit. To address this, place the unmixed epoxy in an old cooler or refrigerator and use an incandescent bulb to keep it warm. Or, you keep it in your warm house until you’re ready to use it.

In any case, I have several documented ways of heating a boat workshop (garage) enough to work the milder days of winter.